E le karolo ea bohlokoa indastering ea kaho, ho roala ka botlalo ho phetha karolo ea bohlokoa.Lilemong tse mashome a mahlano tse fetileng, li-fasteners li 'nile tsa sebelisoa haholo indastering ea kaho le lisebelisoa tse ling tsa mechine.Ka lebaka la ntlafatso e akaretsang ea katleho le matla a thepa ea mohaho, boima ba 'mele ba mehaho bo ntse bo hōla ka tsela e bobebe,' me karo-karolelano ea matla ho boima ba thepa ea eona e ntse e eketseha.Mohaho o bobebe haholo hase ntho e ntle, ho hanyetsa ha oona moea le tšusumetso ho fokotseha butle-butle, kahoo ho na le kotsi ea tšireletso ha re sebelisa mehaho ena.Nakong e fetileng, batho ba bang ba ne ba nahana hore mohaho o ka hahoa feela ka ho itšetleha ka boima ba mohaho ka boeona le ho khomarela seretse, empa ha ho joalo, mohaho leha e le ofe ha o hahuoe feela ka seretse, lekhetlong lena kaofela Mechanical. li-fasteners joalo ka likonopo li bapala karolo ea tsona.E le ho etsa hore ho be le mefokolo ea sebopeho e bakoang ke ho fokotsa boima ba 'mele.Ha boima ba likarolo tsa mohaho bo ntse bo e-ba bobebe, molumo oa bona o boetse oa fokotseha, e le hore sebaka seo khoele e feletseng e kenngoeng ho sona e fokotsehile ka tsela e tšoanang.Ke ka lebaka lena matla a khoele e feletseng a hlokahalang hore a eketsehe, 'me ts'ebetso ea eona E tlameha ho tsejoa ka ho feletseng, e le ho netefatsa tšireletso ea mohaho, hape e ntlafatsa ho hanyetsa moea le ho hanyetsa tšusumetso ea mohaho.U se ke ua nyenyefatsa phello ea khoele e feletseng, eo ka linako tse ling e phethang karolo e kholo.

Li-ankora ke tsa mefuta e latelang:

(1) Boutu ea ankora ea katoloso

Katoloso ea liboutu tsa ankora, tse bitsoang liboutu tsa katoloso, li sebelisa motsamao o lekanyelitsoeng oa khoune le letlapa la katoloso (kapa sleeve ea katoloso) ho ntšetsa pele katoloso ea letlapa la katoloso, ho hlahisa matla a ho atolosa le ho atoloha ka konkreite leboteng la lesoba, le ho hlahisa. ho ntsha bohanyetsi ka ho hohlana ka ho kuta.Karolo e hlokomelang ho tiisetsoa ha sengoathoana se hokahaneng.Li-bolts tsa anchor tsa katoloso li arotsoe ka mofuta oa taolo ea torque le mofuta oa taolo ea phalliso ho latela mekhoa e fapaneng ea taolo ea matla a katoloso nakong ea ho kenya.Ea pele e laoloa ke torque, 'me ea morao-rao e laoloa ke ho falla.

(2) Bolutu ea ankora ea mofuta oa Reaming

Li-ankora tsa mofuta oa reaming, tse bitsoang liboutu tse ntseng li tsoela pele kapa li-grooving bolts, li ntse li phunya hape 'me li khutlisetsa konkreite botlaaseng ba lesoba le phuntsoeng, li sebelisa mochini o kenang lipakeng tsa bokaholimo ba konkreite bo entsoeng ka mor'a ho tsosoa le hlooho ea katoloso ea boutu ea ankora. ., karolo e hlokomelang ho tiisetsoa ha sengoathoana se kopantsoeng.Liboutu tsa ankora tsa Reaming li arotsoe ka li-pre-reaming le ho ikemela ho latela mekhoa e fapaneng ea ho tsosolosa.Ea pele ke ea pele ho grooving le ho tsosolosa ka sesebelisoa se khethehileng sa ho phunya;bolt ea morao-rao ea ankora e tla le sesebelisoa, se itšebetsang le ho tsosolosa nakong ea ho kenya, 'me grooving le ho kenya li phethoa ka nako e le' ngoe.

(3) Liboutu tsa ankora tse tlanngoeng

Liboutu tsa ankora tse tlanngoeng, tse tsejoang hape e le liboutu tsa lik'hemik'hale tse tlamang, tse bitsoang liboutu tsa lik'hemik'hale kapa liboutu tse tlamang, li entsoe ka likhomaretsi tse khethehileng tsa lik'hemik'hale (sekhomaretsi se tiisang) ho khomarela le ho lokisa li-screws le liphaephe tse kentsoeng ka hare ho mekoti ea ho cheka ea likaroloana tsa konkreite.Mosebetsi oa ho kopanya le oa ho koala pakeng tsa sekhomaretsi le screw le sekhomaretsi le lebota la lesoba la konkreite ho hlokomela karolo e khomaretsoeng karolong e hokahaneng.

(4) Ho lema lik'hemik'hale tsa tendon

Mokotla oa ho lema lik'hemik'hale o kenyelletsa sekoahelo sa tšepe se entsoeng ka khoele le molamu o molelele oa screw, e leng thekenoloji ea ho hokahanya ha ankora e sebelisoang haholo lisakeng tsa boenjiniere tsa naha ea heso.The anchorage ea lik'hemik'hale ho lema mekoallo e tšoana le ea bonding anchor bolts, empa hobane bolelele ba lik'hemik'hale lema mekoallo le likurufu tse telele ha e na moeli, ho tšoana le anchorage ea lahla-ka-sebaka mekoallo ea konkreite, le ho senya foromo. e bonolo ho e laola, 'me ka kakaretso e ka laoloa e le tšenyo ea litšepe tsa ankora.Ka hona, e loketse khokahano e tiileng ea litho tsa meralo kapa litho tseo e seng tsa meralo tseo matla a tsona a tsitsitseng le a seismic a leng ka tlase ho kapa a lekanang le 8.

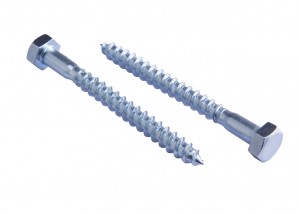

(5) Likurufu tsa konkreite

Sebopeho le mokhoa oa ho tiisa oa li-screws tsa konkreite li tšoana le li-screws tsa lehong.Ho sebelisoa mokhoa o khethehileng oa ho phutha le ho tima sekoti se thata le se bohale sa khoele.Nakong ea ho kenya, sekoti se otlolohileng se nang le bophara bo fokolang se phunngoa pele, ebe sekoti se phunyeletsoa, ho sebelisa khoele le lesoba.Ketso ea occlusal pakeng tsa konkreite ea lerako e hlahisa matla a ho hula 'me e hlokomela karolo e khomaretsoeng likarolong tse kopantsoeng.

(6) Ho thunya lipekere

Ho thunngoa Nail ke mofuta oa lipekere tsa tšepe tse thata haholo, tse kenyelletsang li-screws, tse khannoang ke sethunya, ka konkreite, 'me li sebelisa mocheso oa eona o phahameng (900 ° C) ho etsa lipekere tsa tšepe le konkreite li kopantsoe ka lebaka la ho kopana ha lik'hemik'hale le ho koala.Lemoha anchoring ea likarolo tse hokahaneng.