Lebitso la sehlahisoa: Welding Nuts

Boholo: M8-M24

Kereiti: 6.

Lintho tse Tšepe: Tšepe/35k/45/40Cr/35Crmo

Bokaholimo: Botho, Zinc e Natetsoe

Tloaelo: DIN928, DIN929

Ha ho bapisoa le linate tse tloaelehileng, linate tsa welding li loketse ho chesoa.Ka kakaretso li entsoe ka lisebelisoa tse chesehang 'me li tenya ebile li loketse ho cheselletsa.Welding e lekana le ho fetola likarolo tse peli tse arohaneng ka kakaretso, ho qhibilihisa tšepe ka mocheso o phahameng le ho e kopanya.Ka mor'a ho pholile hammoho, li-alloys li tla ekeletsoa bohareng, 'me ka hare ke phello ea matla a limolek'hule,' me matla ka kakaretso a feta a 'mele oa motsoali.Teko ea liparamente tsa welding e ipapisitse le boholo ba fusion ea weld, mme liparamente tsa welding li lokisoa ho latela boholo ba fusion ho fihlela mefokolo e felile.Ha e le hantle, boleng ba ho tjheseletsa bo amana le phekolo ea pele ho tjheseletsa, joalo ka ho hloekisa, matheba a oli, joalo-joalo, ka hona, tšebeliso ea linate tsa weld e pharaletseng haholo.Litlhokomelo tsa ho sebelisa linate tsa welding: 1. Khase e sireletsang ke argon.2. Bolelele ba electrode ea tungsten e hlahelletseng ho tloha molomong oa khase.3. Bolelele ba arc tjheseletsa ke ka go tlhaolega 2 ~ 4mm ha tjheseletsa tšepe e tloaelehileng, le 1 ~ 3mm ha tjheseletsa tšepe e sa hloekang.Haeba e le telele haholo, ts'ireletso ha e ntle.4. Ho thibela moea le moea.Libakeng tse nang le moea, etsa bonnete ba hore u nka mehato ea ho thibela letlooa, 'me u nke mehato e nepahetseng ea moea ka tlung.5. Sebelisa motlakase o nang le litšobotsi tse ka ntle tse otlolohileng, 'me u sebelise polarity e ntle (terata e hokahane le palo e fosahetseng) ha e le DC.6. Ka kakaretso e loketse ho tjheseletsa ha lipoleiti tse tšesaane tse ka tlase ho 6mm, 'me e na le litšobotsi tsa sebopeho se setle sa seam seam le deformation e nyenyane ea welding.7. E le ho thibela ketsahalo ea li-welding pores, likarolo tsa welding li tlameha ho hloekisoa haeba ho e-na le mafome, tšilafalo ea oli, joalo-joalo 8. E le ho etsa hore khase ea argon e sireletse letamo la ho chesella hantle le ho tsamaisa ts'ebetso ea welding, mohala o bohareng oa electrode ea tungsten le workpiece sebakeng sa welding ka kakaretso e lokela ho boloka angle ea 80-85 °, 'me lehlakoreng le pakeng tsa terata ea ho tlatsa le holim'a workpiece e lokela ho ba e nyenyane ka hohle kamoo ho ka khonehang.Hangata hoo e ka bang 10 °.

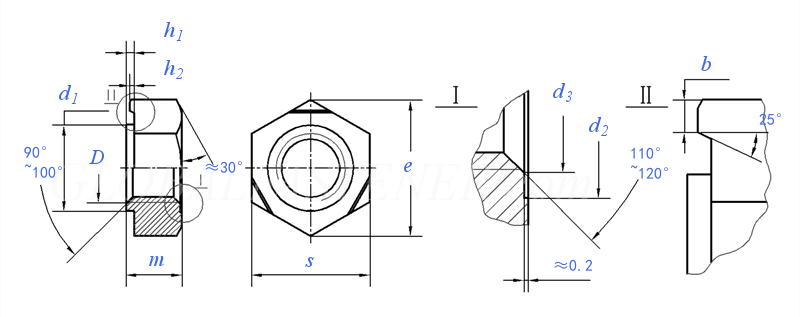

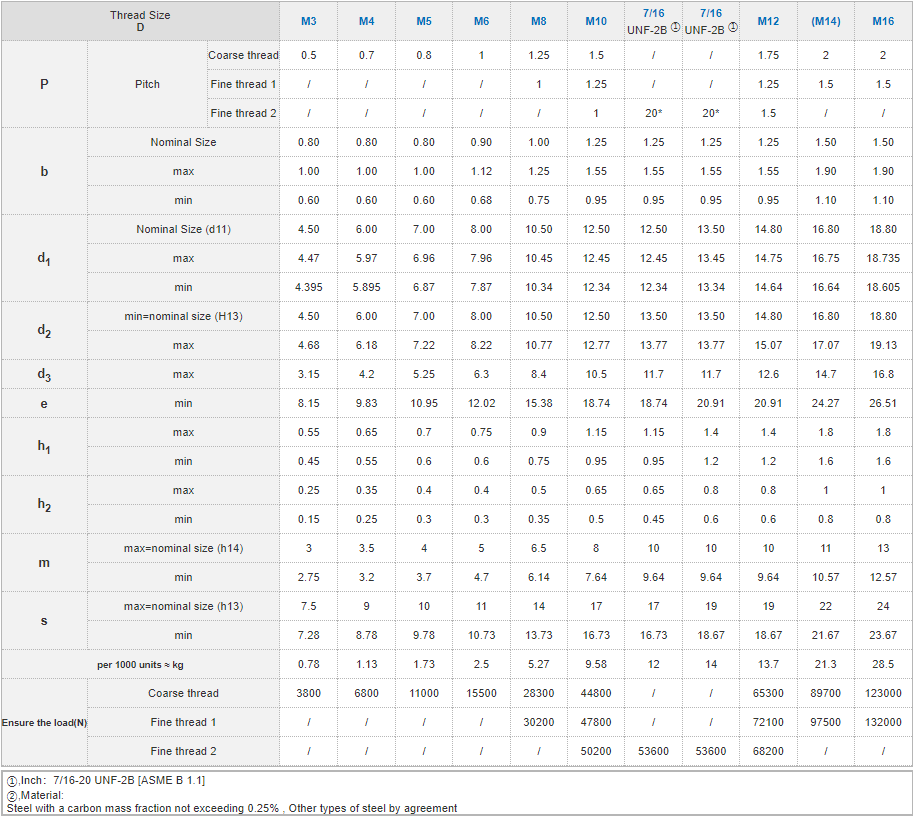

DIN 929 - 2013 Hexagon Weld Nuts